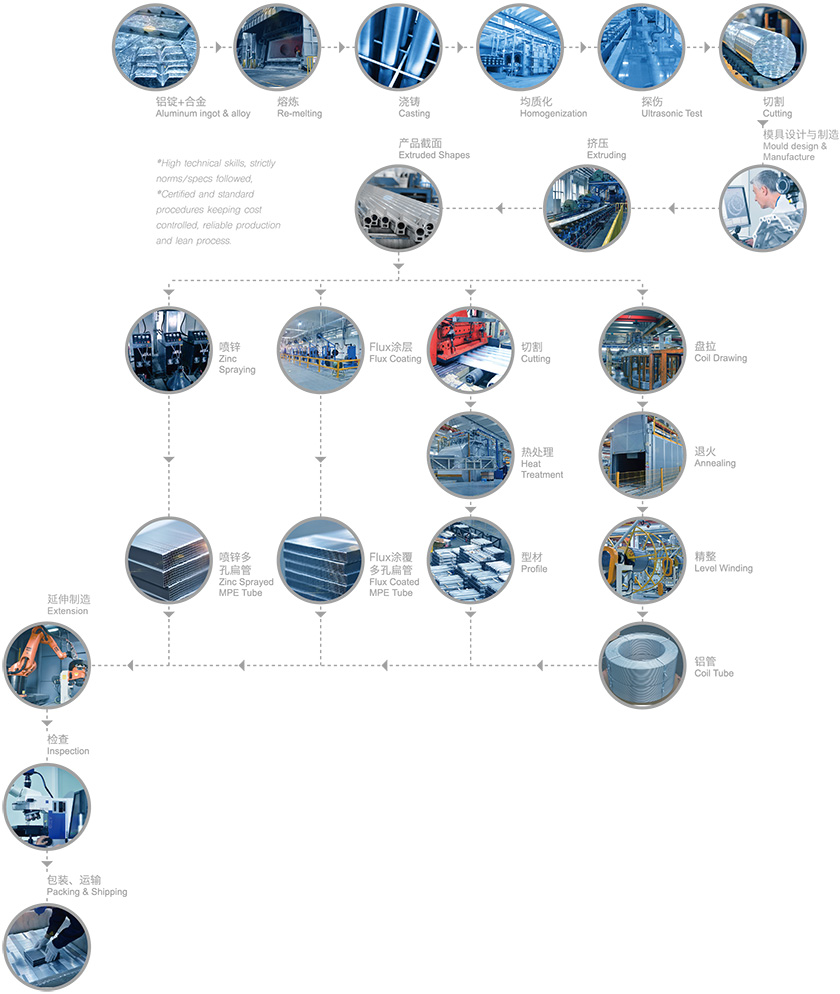

Perfect Process Chain

We provide our customers with basic processes for aluminum processing from aluminum alloy smelting and casting, mold development, extrusion molding, heat treatment, etc., as well as extended manufacturing processes for automatic welding in the field of new energy vehicles. In the automotive, aerospace, rail transportation and other fields, we can meet the high performance structural parts, safety parts delivery requirements.

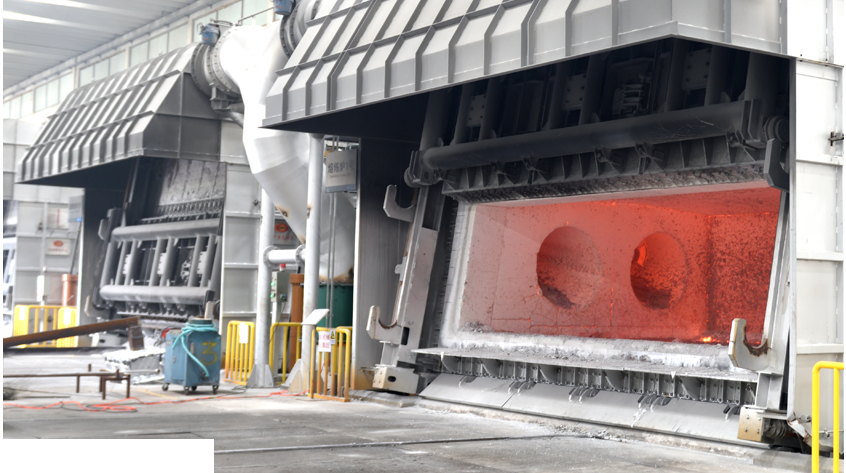

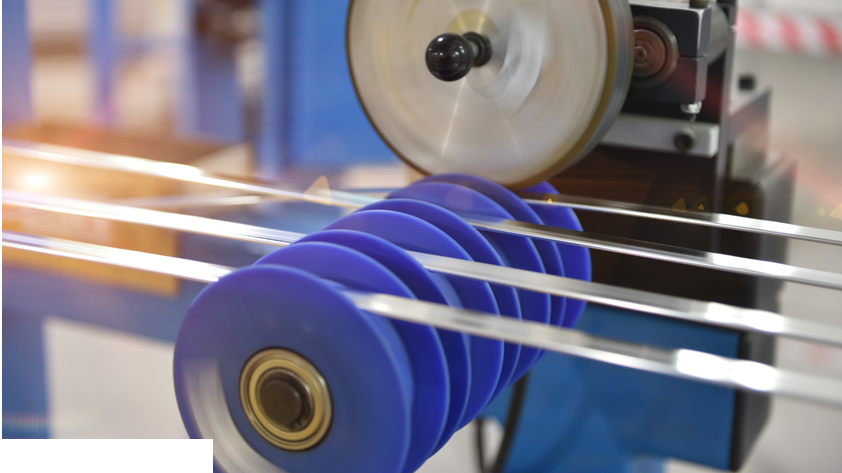

Manufacturing equipment

We have world-class aluminum alloy smelting and casting system equipment, aluminum extrusion equipment up to 100MN, and fast and advanced mold development and manufacturing system equipment (based on 3D metal cladding technology).For customers in the field of new energy vehicles, we have automatic welding station, CNC machining centers, high-efficiency precision machining centers and other aluminum alloy materials to extend production and production equipment.

Production Capacity

It is estimated that by 2020-2025, we can provide customers with high-grade aluminum production capacity of 250,000-300,000 tons per year.

Top

Top